Tel Aviv University and Aviv Analytical

Introduction

Comprehensive two dimensional GCxGC-MS significantly improves the separation of the GC. However, it suffers from complexity and high cost of purchase and maintenance cooling gases. In addition, with standard electron ionization the molecular ions are often weak or absent, particularly in the analysis of complex hydrocarbon mixtures.

We developed Pulsed Flow Modulation (PFM) for obtaining GCxGC-MS with supersonic molecular beams (SMB) (also named Cold EI) based on quadrupole mass analyzer and without any added cooling gas. For further information on the concept of Pulsed Flow Modulation GCxGC please read M. Poliak, M. Kochman and A. Amirav, "Pulsed Flow Modulation Comprehensive Two Dimensional Gas Chromatography" J. Chromatogr. A. 1186, 189-195 (2008) (also Israel patent number 176724 and USA patent number 7518103).

In PFM-GCxGC-MS with Cold EI, sample compounds which elute from the first GC column are temporarily stored in a fused silica transfer line and are pulsed periodically injected by ~25 ml/min He gas pulse into the second column. After the pulse, ~20 ml/min He develops the chromatography in the second column for a few seconds (typically 4s). PFM is simple to construct, does not require any added gas with Cold EI and the injection time can be tuned, hence PFM-GCxGC-MS with Cold EI is enabled with quadrupole MS. The increased PFM second GC column flow rate is seamlessly handled by the Cold EI nozzle vacuum chamber.

We combined PFM-GCxGC with the Aviv Analytical 5975-SMB GC-MS with Cold EI. PFM-GCxGC-MS with Cold EI combines the improved separation of GCxGC with the features of Cold EI of enhanced molecular ions and extended mass spectral isomer and isotope information for the provision of ultimate sample information. Unique to PFM-GCxGC-MS with Cold EI is that as the second dimension elution time is increased the molecular ion mass is reduced for easier GCxGCxMS like identification.

Keep reading to find out how the Aviv Analytical 5975-SMB GC-MS with Cold EI enables effective PFM-GCxGC-MS with Cold EI and provides ultimate level of information with an example of the analysis of JP8 jet fuel (with some Biodiesel related FAMEs). This article also describes and exposes the emergence of the novel concept of GCxGCxMS.

Pulsed Flow Modulation GCxGC (PFM-GCxGC) is fully described in details in references 1-3. Thus, it will be only briefly described here with reference to Figure 1 below that shows the Aviv Analytical Pulsed Flow Modulation GCxGC control software window that includes in its left side a schematic diagram of the pulsed flow modulation components. The main idea behind PFM-GCxGC is that by properly tuning flow directions and rates one can convert the continuous GC output gas flow rate from the first analytical column A into discrete gas pulses for their pulsed injection into the second GCxGC analytical column B. As shown in Figure 1 left side diagram, the sample compounds elute from column A into a storage transfer line (typically 50 cm 0.53 mm I.D. deactivated fused silica capillary) through a first T connector. The storage transfer line is connected to the second GCxGC analytical column B via a second T connector. Both T connectors are further connected via a first gas transfer line A and a second gas transfer line B respectively to a three-way solenoid valve that is controlled by the Aviv Analytical PFM operational software, which controls the direction of helium flow. At a given time after the storage transfer line is almost full (chosen to be about 4 s), a pulse of about 0.3 seconds of typically 25 ml/min helium is directed by the solenoid valve into the first T connector, and the previously eluted sample compounds which were stored in the storage transfer line are quickly flushed into the second analytical column B while temporarily stopping the first analytical column A flow. After this short gas flow pulse, the three-way solenoid valve changes its direction for a few seconds (in our case 4 s), the flow in gas transfer line A stops while the flow in the second gas transfer line B commences at a lower flow rate such as 20 ml/min, since transfer line B has a higher flow impedance than transfer line A (The solenoid valve provides constant pressure). This relatively lower flow rate enables the elution and analysis of sample compounds in the second GCxGC analytical column B, while the sample which elutes from the first analytical column A, is stored in the storage transfer line. A main feature of the pulsed flow modulation is that the short, high flow rate pulse, which flushes the sample from the storage transfer line into the second analytical column B, also simultaneously stops the elution of sample compounds from the first analytical column A. The short high flow rate pulse creates a higher pressure at the first T connector, which not only stops the first analytical column flow, but could also slightly reverts the gas flow back into the column from its output end.

Such column flow stopping, however, is only temporary, for about 5% or less of the time, thus not significantly affecting the GC separation of the first column. In addition, the about 20 times higher flow rate in the second GCxGC column B than in the analytical column A compresses in time the sample compounds that are pulsed injected into the second column and the injection pulse width (in time) can be tuned, for example a cycle time of 4s divided by the flow rate ratio of 20 results in an injection pulse width of 200 msec. As a result, PFM-GCxGC can be coupled with quadrupole MS despite its limited scan speed.

Analytical Conditions and Method Optimization Considerations:

In this section we outline the full range of experimental parameters used in the PFM-GCxGC-MS with Cold EI and explain some of the important considerations behind the selection of central parameters.

System: Aviv Analytical 5975-SMB GC-MS with Cold EI system that is based on the combination of an Agilent 5975 MSD with the Aviv Analytical supersonic molecular beam interface and its unique fly-through ion source.

Sample: Jet fuel JP8 spiked with 50 ppm each methyl palmitate, methyl heptadecanoate and methyl stearate. Injection: 0.5 µL at 250ºC with split ratio of 200 for about 2.5 µg on-column jet fuel.

1st dimension analytical column: 20 m, 0.15 mm ID, 0.15µ film Rxi-5Sil MS.

2nd dimension analytical column: 3 m, 0.32 mm ID, 0.25µ film Rxi-17Sil MS.

He first column flow rate: 0.5 ml/min.

Pulsed Flow Modulation gas transfer lines: 70 cm 0.25 mm ID capillary transfer line to the second dimension column entry side and 50 cm 0.32 mm ID capillary transfer line to the storage capillary at its first analytical column exit side.

Sample Storage Capillary: 50 cm of 0.53 mm ID deactivated transfer line by Agilent.

Pulsed Flow Modulation helium flow rates: about 18 ml/min during the injection time and 13 ml/min during the second column separation cycle time.

GC Oven Temperature Program: 80°C with 1°C/min to 90°C followed by 2°C/min to 110°C followed by 3°C/min to 140°C followed by 4°C/min to 180°C followed by 5°C/min to 230°C with waiting period of 6 min at 230°C for total run time of 56 min.

PFM Pressure Program: See below in the Aviv Analytical PFM-GCxGC screen.

Cold EI Fly-Through Ion Source: 8 mA emission, 70 eV electron energy, 62 ml/min total He makeup and PFM flow rates using 700 mBar nozzle backing pressure. The PFM gas requirement is offset by reduced nozzle make-up gas thus the PFM by itself does not add any gas requirement.

SMB transfer-line temperature: 250ºC.

5975 mass spectrometer: 50-320 amu at 15.6 Hz scanning frequency (0 A/D samples).

5975 mass spectrometer tune change: The faster than usual scan speed introduced negative mass shift of about 0.17 amu that was corrected via the change in the manual tune screen of MASSOFFSET from -34 to -24 in the tune values. No other change was made in the tune.

Electronic Pressure and Flow Controller: Aviv Analytical uses the Alicat MC200 EPC/EFC.

GCxGC method development is known to be more involved than standard GC method development. However, once the PFM-GCxGC concept is understood its method development can be relatively easy to implement and optimize based on the following considerations.

First Dimension GC Column. In PFM-GCxGC unlike in thermal modulation GCxGC the first dimension column should be with small ID to minimize the column flow rate and as a result minimize the typically 20 times higher second dimension column flow rate in order to improve the second dimension separation. Thus, we selected the 0.15 mm ID column which enables standard operation with 0.5 ml/min instead of 1 ml/min with standard 0.25 mm ID columns.

Second Dimension GC Column. In PFM-GCxGC it should be as big as possible for best separation and minimal flow impedance under high column flow rate limits. However, it must enter into 0.53 mm ID storage transfer line hence 0.32 mm ID column is the most suitable. The second column sorption phase selection is the same as in thermal modulation GCxGC and 50% phenyl is a reasonable choice. The length and film thickness selection are a matter of GCxGC second dimension time span which for the early eluters is usually too narrow while for the late eluters it is usually too long. Thus, it is a matter of sample based optimization and we selected 0.25 µ film thickness and 3 meters length for the jet fuel sample.

Storage Capillary Length. This length selection depends on the choice of second dimension cycle time which is 4 s in our case and first dimension column flow rate which was 0.5 ml/min. In this case the eluting volume in 4s is 33.3 µL and the storage capillary should have volume bigger than that. For 0.53 mm ID transfer line capillary this means that its net length should be longer than 17 cm. We selected 50 cm to have freedom in the choice of flow rate and cycle time as some added length does not degrade the performance.

Pulse Duration Time and its PFM-GCxGC Optimization. We selected, as shown in figure 1, 0.36 s. The selection of injection pulse duration and second column flow rate is optimized via the use of a steady flux of pentane from a sampler. We used a 0.5 ml syringe with ChromatoProbe vial inside it that was loaded with pentane and inserted into the injector to serve as a diffusion source of steady flux of pentane. Aviv Analytical provides this syringe and vials with its PFM GCxGC kit. After 2 minutes 1st column transit time one can operate the MS with SIM on m/z=72 of pentane and see the effect of all the PFM parameters on the injection time and pulse shape and width. The goal is to have injection time of about 200 ms which was obtained in our case with 1900 mBar absolute (~13 PSIG) and 0.36 sec injection pulse duration. The actually produced pulse width was faster than 0.36 s and was about 0.15-0.2 s.

PFM Gas Source Lines. In PFM-GCxGC the gas line that is connected into the first column side must be with smaller flow impedance than the second gas line so that when the flow is switched into it the pressure at the first column output will be higher and as a result the first column flow rate will be halted for the duration of the second dimension injection time of ~0.2 s. We found that the use of 0.32 mm ID capillary for the first column side and 0.25 mm ID capillary for the second dimension column side are adequate and we even further prolonged the 0.25 mm ID capillary length by about 20 cm.

PFM Pressure Program. Similar to thermal modulation, as the GC oven temperature is increased the time spread in the second column is increased and at some GC oven temperature there is a risk of having second dimension elution in the next cycle (known as wrap around). Thus, in order to prevent that adverse effect we used second column flow program via the second column head pressure program as described in the PFM software window shown in Figure 1. Accordingly, the pressure was gradually increased from constant 1900 mBar for 12 min, up to 2400 mBar at 30 min and up to 2500 mBar at 53 min with pressure updates every minute. This pressure program worked very well to eliminate the wrap around problem.

GC Oven Temperature Program. The GC oven temperature program is also important for the GCxGC-MS performance. For optimal first dimension separation the peak width should be about three second dimension cycles. As a result, the temperature program should be slow such as with 2ºC/min. In addition, the GC program also affects the elution time spread in the second dimension. The slower the GC oven temperature program the lower are the sample compounds elution temperatures and thus the greater is their time spread in the second column elution. Thus, in order to reduce the problem of wrap around and increase the second column time spread for the early eluters one may wish to have a GC oven temperature program that its rate is gradually increased with time such as 1ºC/min initially than 2ºC/min and than 3ºC/min instead of fixed 2ºC/min.

Backflush. One of the advantages of PFM GCxGC over thermal modulation GCxGC is that the PFM-GCXGC device can also serve as a built-in backflusher device since it includes a gas supply junction behind the flow impedance of the second dimension GCxGC column. Thus, as shown in Figure 1, after 53 min the pressure program was switched into backflush mode with 30 ml/min which is about 3000 mBar and in addition, the Agilent 7890 GC injector pressure was reduced to 1 PSIG at that time. Backflush is a known effective technique to keep the first dimension column clean from low volatility compounds such as potential oil impurities in jet fuel.

Backflush. One of the advantages of PFM GCxGC over thermal modulation GCxGC is that the PFM-GCXGC device can also serve as a built-in backflusher device since it includes a gas supply junction behind the flow impedance of the second dimension GCxGC column. Thus, as shown in Figure 1, after 53 min the pressure program was switched into backflush mode with 30 ml/min which is about 3000 mBar and in addition, the Agilent 7890 GC injector pressure was reduced to 1 PSIG at that time. Backflush is a known effective technique to keep the first dimension column clean from low volatility compounds such as potential oil impurities in jet fuel.

5975 Scan Speed. We used 15.6 Hz that as shown below, is sufficient for the jet fuel PFM GCxGC-MS with Cold EI. For the mass spectral range of 50-320 amu this is a scanning rate of 4200 amu/s. The Agilent 5975 MSD is capable of using fast scan mode up to about 8000 amu/s. However, we found that when the fast scan mode is used, isotope abundance information is lost since probably the mass spectral resolution is deteriorated. Since we believe that GCxGC-MS is all about the provision of best sample identification information, we prefer to have somewhat slower than optimal scan speed than losing the ability to provide elemental formula with our TAMI software for improved sample identification. We assume that the newer Agilent 5977 has faster scan speed without losing resolution.

PFM-GCxGC-MS with Cold EI analysis of Jet Fuel

We evaluated and demonstrated the Aviv Analytical PFM-GCxGC-MS with Cold EI in the analysis of JP8 jet fuel that was spiked with 3 Biodiesel related FAMEs. In this article we prefer to emphasis on showing the raw data without the two dimensional maps as while these maps excel in the provision of group type information as provided by GCxGC-FID, they are silent about the obtained mass spectral information. However, a 2D map is shown at the bottom (Figure 8) for qualitative data assessment. Accordingly, in Figure 2 we show the total ion mass chromatogram of the PFM-GCxGC-MS with Cold EI of jet fuel (upper trace) and a representative Cold EI MS of n-C14H30. As shown, the usual jet fuel GC-MS hump with peaks is now dissected into groups of second column cycle times which do not have wrap around as concluded from the fact that all the group of peaks end at the baseline. The Cold EI mass spectrum of n-C14H30 exhibits the usual enhanced molecular ion plus all the typical hydrocarbon fragments as well as the correct isotope distribution of the molecular ion that can be inverted with the Aviv Analytical TAMI software into elemental formula for the confirmation of NIST library identification. Despite the cooling effect, tetradecane (n-C14H30) was identified by the NIST library with a matching factor of 785 and reversed matching factor of 790 which are relatively low due to the enhanced molecular ion. However, the NIST identification probability was 73.1% which is much higher than obtained with standard EI for hydrocarbons such as tetradecane (typically less than 40%) since the enhanced molecular ion is the only compound specific ion in hydrocarbons mass spectra as discussed in our post on the topic. Thus, while we get a lower fit we obtain better hit and identification by the library with Cold EI MS. The TAMI software confirmed the NIST identification with a very high matching factor of 998 and made it unambiguous.

.

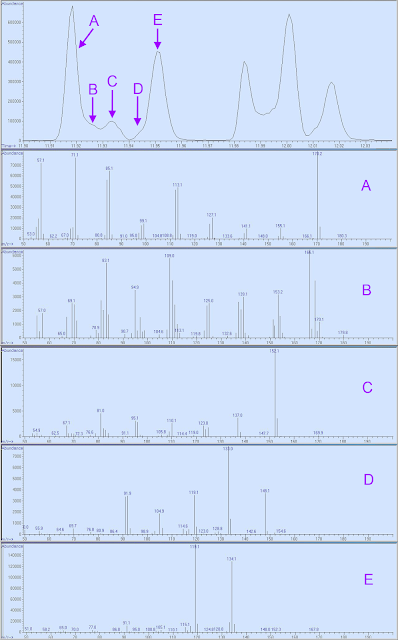

In Figure 3 we show a section of the total ion count mass chromatogram of two cycles of PFM-GCxGC-MS with Cold EI of jet fuel JP8 (upper trace) and five Cold EI mass spectra A-E of GCxGC-MS peaks A-E of the first (left) GCxGC cycle from about 11.90 min to 11.97 min. Several observations are concluded from Figure 3.

- The second dimension GC-MS trace exhibits a mass chromatogram with several peaks. Three peaks are clearly separated while two "shoulders" of peaks hint on additional peaks for at list total of five peaks.

- The second GCxGC cycle has a different structure and also with five compounds peaks.

- The five mass spectra that are plotted on the A-E traces where obtained at five different elution times and are each unique and with abundant molecular ions. A was identified as a branched isomer of C12H26, B was identified as a co-elution combination of C12H24 and C12H22 which are unsaturated and doubly unsaturated alkenes, C was identified as trans-decaline 2-methyl or one of its isomers, D was identified as one of the pentamethyl benzene isomers and E was identified as tetramethyl benzene (one of its isomers).

- A very interesting observation is that a clear correlation exists between the second dimension elution time and molecular weight of that sample compound. The greater is the second dimension elution time the smaller is the mass of the eluting compounds. In other words, in a given cycle, the greater the sample polarity the smaller is its mass. This correlation simplifies and helps in sample identification and is related to the emergence of a novel concept of GCxGCxMS.

.

GCxGCxMS is a new and interesting concept for having three dimensions of separation. For the original reference to the concept of GCxMS please read F. C. Y. Wang, K. N. Wan and L. A. Green "GCxMS of diesel: A two dimensional separation approach" Anal. Chem. 77, 2777-2785 (2005). According to Wang and co-workers, if the mass spectrum is obtained with a soft ionization method such as field ionization and as a result only molecular ions are generated, the separation of the GC and MS are orthogonal and can yield two independent dimensions of separation of the GC and MS hence named GCxMS. If only molecular ions are produced the mass spectrometer possesses a separation space of the mass divided by the few isotopes of the molecular ions. While unlike standard EI Cold EI provides trustworthy molecular ions, in contrast to field ionization it also produces the usual EI fragments. We note that in GCxGC-MS the mass range of the molecular ions is limited and in our case in a given one GCxGC cycle as shown in Figure 3 it is between 170 and 134 amu. Thus, in GCxGC-MS with Cold EI, upon the exploration of Cold EI mass spectra in a given second GC dimension cycle, any new high mass peak in this 134-170 amu mass range must belong to a new compound. Consequently, the high mass spectral range provides an additional dimension of separation unlike in standard EI in which the molecular ion can be fully missing for branched hydrocarbons or weak and cannot be trusted. Thus, as demonstrated in Figure 3, PFM-GCxGC-MS with Cold EI demonstrates the emergence of novel concept of GCxGCxMS in which the Cold EI mass spectrum provides solid information on the molecular ions hence another dimension of separation.

GCxGCxMS is a new and interesting concept for having three dimensions of separation. For the original reference to the concept of GCxMS please read F. C. Y. Wang, K. N. Wan and L. A. Green "GCxMS of diesel: A two dimensional separation approach" Anal. Chem. 77, 2777-2785 (2005). According to Wang and co-workers, if the mass spectrum is obtained with a soft ionization method such as field ionization and as a result only molecular ions are generated, the separation of the GC and MS are orthogonal and can yield two independent dimensions of separation of the GC and MS hence named GCxMS. If only molecular ions are produced the mass spectrometer possesses a separation space of the mass divided by the few isotopes of the molecular ions. While unlike standard EI Cold EI provides trustworthy molecular ions, in contrast to field ionization it also produces the usual EI fragments. We note that in GCxGC-MS the mass range of the molecular ions is limited and in our case in a given one GCxGC cycle as shown in Figure 3 it is between 170 and 134 amu. Thus, in GCxGC-MS with Cold EI, upon the exploration of Cold EI mass spectra in a given second GC dimension cycle, any new high mass peak in this 134-170 amu mass range must belong to a new compound. Consequently, the high mass spectral range provides an additional dimension of separation unlike in standard EI in which the molecular ion can be fully missing for branched hydrocarbons or weak and cannot be trusted. Thus, as demonstrated in Figure 3, PFM-GCxGC-MS with Cold EI demonstrates the emergence of novel concept of GCxGCxMS in which the Cold EI mass spectrum provides solid information on the molecular ions hence another dimension of separation.

In Figure 4 we show the reconstructed mass chromatograms (RSIM) of PFM-GCxGC-MS with Cold EI of jet fuel JP8 in the elution time window of 11.90–12.04 minutes (the same as in Figure 3) using the m/z values of 170.2. 168.2, 166.2, 152.1, 148.1 and 134.1. As demonstrated, each of these six masses that are concluded to be different molecular ions from the Cold EI mass spectra of Figure 3, provides a distinct RSIM peak with a distinct second dimension elution time that confirms the fact that the second dimension GCxGC includes six identified sample compounds as described and named in point 3 above.

In Figure 5 we show at the upper trace another section of the PFM-GCxGC-MS of jet fuel, and this time in a higher elution time window of 28.70-28.77 min. As expected, the number of co-eluting compounds is now bigger and their second dimension GCxGC separation becomes harder. Furthermore, we deliberately selected an elution time window which is of low intensity (<1% of the full chromatogram scale for most compounds) to include a demonstration of the PFM-GCxGC-MS with Cold EI sensitivity. The lower traces are of reconstructed mass chromatograms (RSIM) of compounds with identified molecular ions, and as shown eleven such compounds could be extracted with m/z values according to order of elution times of 212.2, 210.2, 196.2, 208.2, 194.2, 192.2, 190.2, 188.1, 174.1, 160.1 and 156.1.

Another unique feature of PFM-GCxGC in contrast to thermal modulation GCxGC is that its second dimension column does not suffer from column saturation effects and its related peak fronting issues even if the first dimension column is saturated. As demonstrated in Figure 6 below, the RSIM mass chromatograms of m/z=142.1 and 140.1 are symmetric and clean from any chromatographic perturbation. In this elution time window m/z=142.1 belongs to n-decane which is the biggest set of GCxGC peaks in the mass chromatogram of jet fuel that is shown in Figure 2 and which brings the first column into some saturation. However, despite this onset of first column sample capacity saturation the second dimension peaks are narrow at about 200 ms peak width, and the m/z=140.2 peak near it is unaffected by it although its height is only a few % of the decane peaks.

Figure 6. Reconstructed (RSIM) mass chromatograms of m/z=142.1 of n-decane (upper trace) at the elution time window of 6.76-7.00 min in which n-decane elutes as the biggest peaks in the jet fuel sample. The RSIM trace of m/z=140.1 of decene is shown at the bottom trace. As demonstrated, all the peaks are narrow and symmetric without any onset of second GC column sample capacity saturation. Click to Enlarge.

Another challenge in jet fuel analysis is the identification and quantification of as low as 5 ppm biodiesel compounds in the jet fuel. We simulated biodiesel as three fatty acid methylester compounds of methyl palmitate, methyl heptadecanoate and methyl stearate spiked at 50 ppm each. As shown in Figure 7, these three FAMEs can be easily located in the full scan mass chromatogram (upper trace) with on-column amounts of 125 pg. We note that the on-column FAMEs amount can be significantly increased if Biodiesel analysis in jet fuel would be the main analysis target. In the middle trace of Figure 7 we show the zoomed m/z=284.3 RSIM trace of methyl heptadecanoate which is represented by two GCxGC peaks. As shown, these two peaks are symmetric, without any ion source related peak tailing and with peak width of about 150 ms. These sharp and symmetric GCxGC-MS peaks which are shared by all the FAMEs demonstrate another unique advantage of PFM-GCxGC-MS with Cold EI of inherent elimination of ion source related peak tailing that hampers the GCxGC-MS separation of thermal modulation with standard EI ion sources. This is the result of using a contact-free fly-through ion source in Cold EI. The signal to noise ratio of the RSIM traces of the 3 FAMEs were above 1000 (peak to peak S/N). The bottom trace in Figure 7 shows the Cold EI mass spectrum of methyl heptadecanoate which is characterized by a dominant molecular ion yet with all the usual fragments including the FAMEs characteristic m/z=74.

In Figure 8 below we show a two dimensional plot of the PFM-GCxGC-MS data. As usual, we can see the group type information data as well as a full qualitative assessment of the degree of orthogonality of the two dimensions of separation. We note that the second dimension elution time of aliphatic compounds is controlled by the pressure program used, which also served to reduce and/or eliminate wrap around. Aviv Analytical data presentation software was used.

In Figure 8 below we show a two dimensional plot of the PFM-GCxGC-MS data. As usual, we can see the group type information data as well as a full qualitative assessment of the degree of orthogonality of the two dimensions of separation. We note that the second dimension elution time of aliphatic compounds is controlled by the pressure program used, which also served to reduce and/or eliminate wrap around. Aviv Analytical data presentation software was used.

|

| Figure 8. A two dimensional plot of PFM-GCxGC-MS with Cold EI data of JP8 jet fuel using the Aviv Analytical qualitative data presentation software. Click to Enlarge. |

.

Conclusions

Pulsed Flow Modulation GCxGC-MS with Cold EI uniquely combines improved GCxGC separation with the superior MS sample identification power of Cold EI. Furthermore, PFM-GCxGC is easier to construct, maintain and operate than thermal modulation GCxGC. Perhaps the most important advantage of PFM-GCxGC is that it is fully compatible with the scan speed of quadrupole mass analyzers in view of its ability to tune the second GC dimension injection time, while with Cold EI its increased ~20-30 ml/min flow rate is seamlessly handled without any use of open split that can lead to reduced sensitivity. As a result, PFM-GCxGC-MS with Cold EI can provide superior combination of improved separation and identification at lower cost of goods compared to thermal modulation GCxGC combination with TOF-MS with standard EI. Admittedly, the second dimension GCxGC separation with PFM is about twice lower (in peak capacity) than of thermal modulation GCxGC due to wider second column injection pulse and higher second column flow rate (even in consideration of the x3 typically longer second column). However, for most GCxGC-MS applications this lower second dimension column separation is fully negated by the full removal of any ion source related peak tailing in Cold EI (which plague standard EI) and by the elimination of adverse second column sample capacity saturation effects. Finally, we found a unique behaviour of PFM-GCxGC-MS with Cold EI of reduced molecular ion masses as the second dimension GCxGC elution time is increased. This important observation emerges from the availability of molecular ions to all the sample hydrocarbons, and it facilitates easier sample identification under partial co-elution conditions. We named this phenomenon as GCxGCxMS.

PFM-GCxGC is now offered for sale by Aviv Analytical for its combination with the Aviv Analytical 5975-SMB GC-MS with Cold EI.

References

- M. Poliak, M. Kochman and A. Amirav "Pulsed Flow Modulation Comprehensive Two Dimensional Gas Chromatography" J. Chromatogr. A. 1186, 189-195 (2008).

- M. Poliak, A. B. Fialkov and A. Amirav "Pulsed Flow Modulation Two-Dimensional Comprehensive Gas Chromatography Tandem Mass Spectrometry with Supersonic Molecular Beams" J. Chromatogr. A. 1210, 108-114 (2008).

- Aviv Amirav, "Pulsed Flow Modulation Gas Chromatography Mass Spectrometry with Supersonic Molecular Beams Method and Apparatus" Israel patent number 176724 (submitted in July 6, 2006) and USA patent number 7518103.

No comments:

Post a Comment